IFE Aufbereitungstechnik GMBH was founded in 1947 as an institute for technical research and development.

Today they are one of the worlds leading manufacturers of vibratory conveying equipment, screening technology and a magnetic separation solutions.

Quality, reliability and efficiency has been IFE’s main focus for past 70 years. Their continual development programme has established them as leading supplier to the global bulk materials handling industry, thus ensuring that their customers benefit from a wealth of experience gained from satisfying numerous applications across a wide and diverse range of industries.

View the range of IFE products below

Filter by Category

Introducing the IFE Aeroseloctor, the ultimate solution for compost processors in tackling contamination and achieving higher recovery rates. The IFE Aeroseloctor is a cutting-edge technology that enables processors to remove contamination efficiently during the composting process. By utilizing advanced screening & air separation techniques, it effectively separates unwanted materials from the compost stream, ensuring a cleaner and more refined final product.

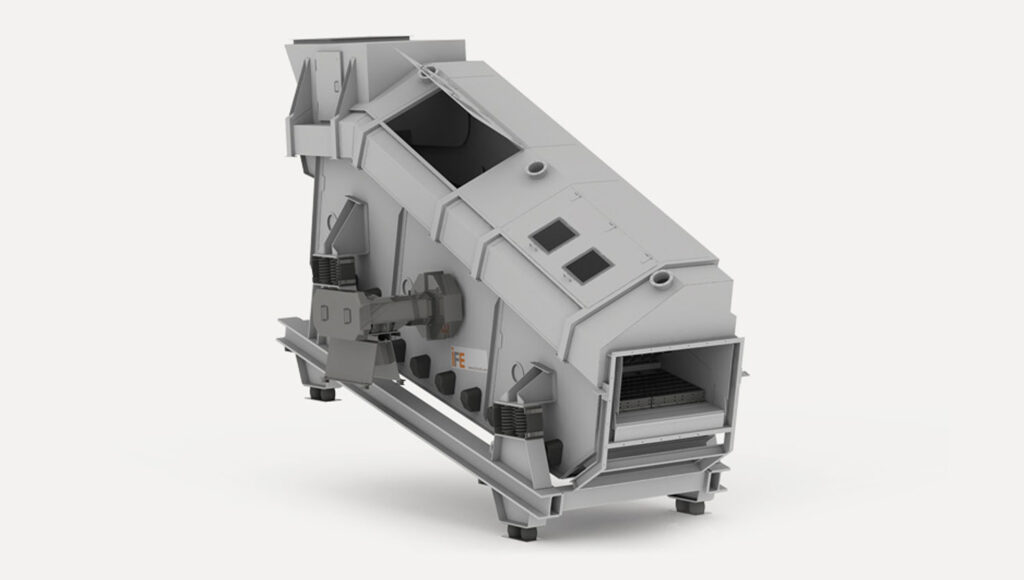

The IFE waste screen provides a single-deck screening solution to the waste management and material recycling sectors. The flat-screen design combines a multitude of advantages, inclusive of unbalanced shaft drive arrangement complete with oil-bath bearing assembly, interchangeable cascading screening panels available in numerous louver-like designs and design concepts to maximise screen open area and throughput performance.

The IFE Trisomat flip-flop screen is designed specifically for processing difficult to handle materials. The construction of the IFE Trisomat flip-screen offers a true flip-flop unique three-phase oscillation action designed to minimise clogging and sticking whilst reducing dynamic load on associated support structures.

The IFE Variomat double-deck waste screen combines an upper louvered-type flat deck waste screen with a resonance system lower deck screening mat arrangement. This combination provides a market leading double-deck screening solution for the processing of numerous types of waste streams and materials.

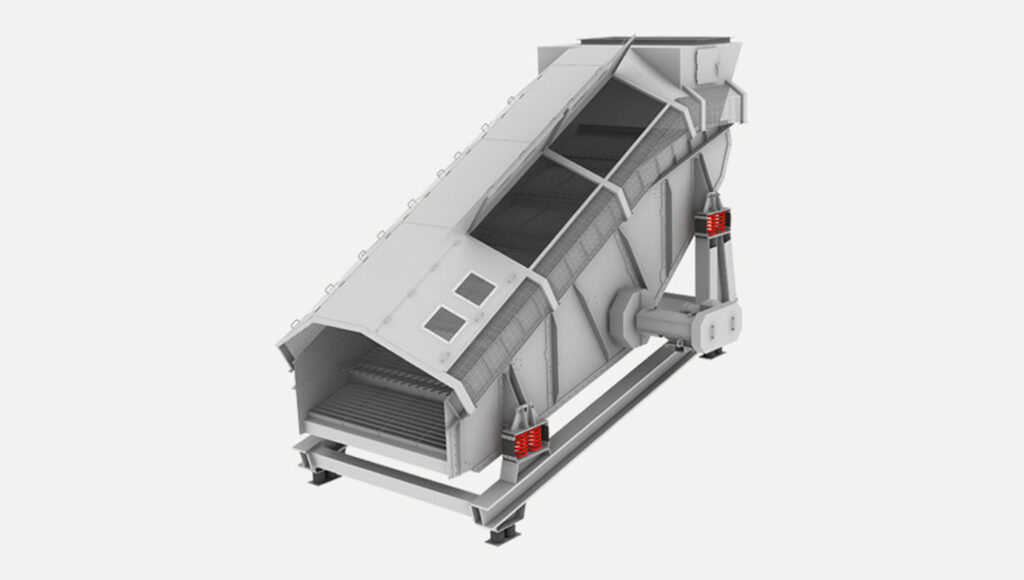

IFE’s range of linear-motion vibrating screens are available in a wide and diverse range of sizes and configurations. Utilised for the processing of dry granular free-flowing materials IFE’s range of linear-motion vibrating screens offer both standard and bespoke configurations to suit any number of applications.

IFE’s range of circular-motion screens offer a reliable and robust solution for the screening of dry granular free-flowing materials. Construction comprises of a bolted and glued frame, complete with cross beams, inclusive of in-house manufactured IFE unbalanced shaft or single IFE unbalance motor drive arrangement. Available in single of multideck configurations IFE’s circular-motion screens provide a universal solution for the screen of bulk materials.

The IFE range of scalping screens are typically employed prior to crushers, mills, and other associated applications. Suitable for coarse, heavy and sticky material this range of screens provides the ability to protect downstream processing equipment by removing large oversize particles. Driven via either IFE’s unbalance motors or exciter drives IFE’s range of scalping screens provide a robust efficient solution for a wide and diverse range of materials.

The IFE sizer offers a multi-deck compact solution for the screening of dry granular free-flowing materials. This range of economical screening equipment can be used for the screening of wide range of materials and products inclusive of meals, additives, animal feeds, flour, food products plus many more derivatives.

Available in numerous materials of construction the IFE sizer provides a compact cost-effective solution to a host of applications.

IFE’s banana screen design can process up to three times the specific feed rate compared to conventional screens. Available in either single of double-deck construction this bolted and glued robust design of screen is suitable for a wide range of applications to satisfy higher processing capacities and increased feed rates.

The IFE hard particle separator and destoner is available in a wide range of sizes and models. Designed to separator lights from heavies, inclusive of 2D/3D separation, this versatile range of equipment can be employed to satisfy a number of applications in the waste management, materials recycling, glass reprocessing and compost industries.

The IFE sort density separator utilises a wide range of technologies for the separation of fine dry free-flowing materials and products. The combination of vibrating screening deck and fluidised bed creates an infinitely adjustable screening action therefore making the IFE sort suitable for a wide range of applications involving the processing of secondary materials, wood, precious metals and feed/food products.

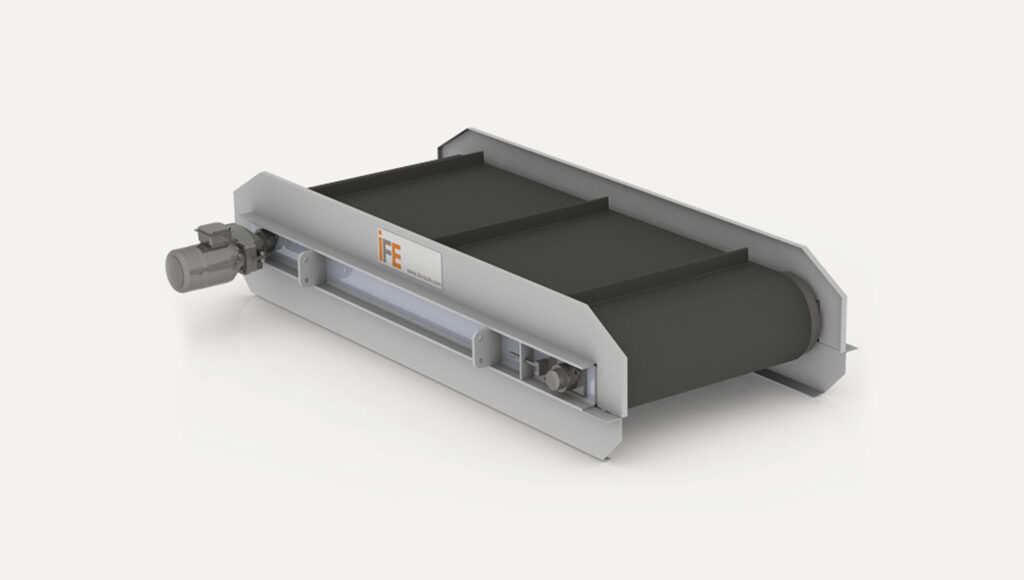

IFE’s range of electromagnetic and permanent overband separators offer a wide and diverse range of solutions for the removal of ferrous impurities from a host of materials. Available is numerous standard sizes and configurations including varying strengths of magnetic fields this range of equipment provides market leading solutions for the waste management, materials recycling, aggregates and mining sectors.

IFE’s range of eddy current separators represent some of the most advanced technologies available for the removal of non-ferrous materials. These market leading solutions cover a wide and diverse range of sizes and designs incorporating up to 3000mm wide belt widths inclusive centric, eccentric and eddy current bar versions.

The IFE range of magnetic drum separators provide an application specific solution for the removal of ferrous materials and particles from bulk materials. This range of equipment can be installed as a standalone solution or combined with other IFE components such as screens, feeders and eddy current separators for specialise applications.

IFE’s high-intensity magnetic separators offer superior separation results for the removal of particles with poor magnetic properties. Typically employed on fine grade materials within the minerals, mining and ash processing markets this range of equipment can provide a dedicated solution for the removal of impurities from various bulk materials.

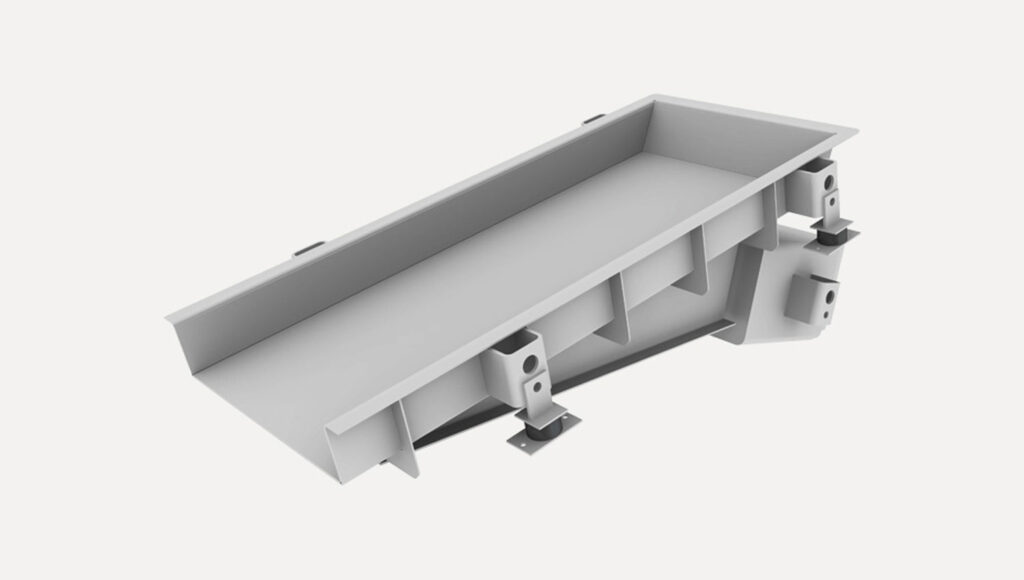

IFE provide a complete range of vibratory feeders for the dosing of numerous bulk materials, utilising either electromagnetic or unbalanced drive arrangements. Correct feed of material is essential for optimising downstream processing therefore the IFE vibrating feeder range can offer both standard and tailor-made solutions to meet a multitude of applications.

IFE’s range of vibratory tubular feeders offer an enclosed design to satisfy applications requiring a dust tight solution to eliminate dust emissions and to prevent ingress of material for cross contamination purposes. Available in a wide range of designs, sizes and configurations utilising either electromagnetic or unbalance drive arrangements this range of equipment provides the perfect solution for the dosing of various materials and products.

Contact Us

Get in touch with MPS PTY

For any enquiries, simply give us a call or contact us via the message form and a member of our friendly team will be in touch to discuss your project needs.